In the realm of facilities management, maintenance work orders play a pivotal role in ensuring the efficient and safe operation of facilities and equipment. These formal documents serve as a roadmap for maintenance and repair tasks, guiding maintenance technicians and contractors in their work.

By centralizing information, facilitating task management, allocating resources, and tracking historical data, maintenance work orders are indispensable tools for maintaining the functionality and longevity of facilities.

What Is a Maintenance Work Order?

A maintenance work order is a formal document that authorizes and outlines maintenance or repair tasks to be carried out on facilities or equipment. It serves as a request for necessary work to be done, detailing the scope of the task, materials required, estimated time for completion, and any specific instructions.

Maintenance work orders are essential for streamlining communication between maintenance managers, technicians, and other stakeholders, ensuring that maintenance tasks are completed efficiently and effectively.

Maintenance Work Order Types

There are various types of maintenance work orders, each serving a specific purpose in the maintenance management process. Understanding the different types of work orders is essential for effectively prioritizing and managing maintenance tasks based on their urgency and impact on facilities and equipment.

Preventive Maintenance Work Orders

Preventive maintenance work orders are scheduled in advance to perform routine maintenance tasks and inspections aimed at preventing breakdowns or failures. These work orders are proactive in nature, focusing on maintaining equipment and facilities in optimal condition to prevent unexpected issues and prolong their lifespan.

Corrective Maintenance Work Orders

Corrective maintenance work orders are created in response to unexpected equipment failures or malfunctions that require immediate attention. These work orders address issues that have already occurred, aiming to restore facilities or equipment to operational status as quickly as possible to minimize downtime and disruptions to operations.

Emergency Maintenance Work Orders

Emergency maintenance work orders are issued for critical repairs that pose a safety hazard or have a significant impact on operations and require immediate resolution. These work orders address urgent issues that must be dealt with promptly to ensure the safety of personnel, prevent further damage, and maintain the continuity of essential services.

Predictive Maintenance Work Orders

Predictive maintenance work orders are based on data and analysis to predict when maintenance tasks should be performed to avoid potential issues in the future. These work orders leverage predictive technologies and condition monitoring to anticipate maintenance needs and proactively address them before they escalate into critical problems.

Maintenance Work Order Process Flow

The process flow of a maintenance work order involves several key steps that guide the initiation, execution, and completion of maintenance tasks. Understanding the process flow is essential for effectively managing maintenance work orders and ensuring that maintenance activities are carried out in a timely and organized manner.

Work Order Initiation and Submission

The maintenance work order process typically begins with the initiation and submission of a work order request. This step involves identifying the maintenance needs, documenting the scope of work, and submitting the request to the appropriate personnel, such as maintenance managers or supervisors.

Work Order Review and Approval

Once a work order request is submitted, it undergoes a review and approval process to ensure that it aligns with the organization’s maintenance priorities, resources, and schedules. During this step, maintenance managers evaluate the work order, assess its urgency and impact, and approve it for execution based on available resources.

Assignment of Work Order to Maintenance Personnel

After a work order is approved, it is assigned to specific maintenance technicians or contractors responsible for carrying out the maintenance task. Assigning work orders to qualified personnel with the necessary skills and expertise is crucial for ensuring that tasks are completed efficiently and according to the required standards.

Execution of Maintenance Task

Once a work order is assigned, maintenance technicians proceed with executing the maintenance task as outlined in the work order. This step involves following the instructions provided in the work order, using the required materials and tools, and completing the task within the specified time frame to ensure facilities or equipment are restored to operational status.

Completion of Work and Closeout of Work Order

Upon completing the maintenance task, technicians verify that the work has been done satisfactorily and meets the specified requirements outlined in the work order. Once the work is validated, the work order is closed out, signifying the successful completion of the maintenance task and allowing for documentation and tracking of work performed.

Documentation of Work Performed for Historical Tracking

The final step in the maintenance work order process involves documenting the work performed for historical tracking and analysis. Maintaining detailed records of completed work orders, including the tasks performed, materials used, time taken, and any issues encountered, enables organizations to track maintenance activities over time, identify patterns, and make informed decisions to improve maintenance practices.

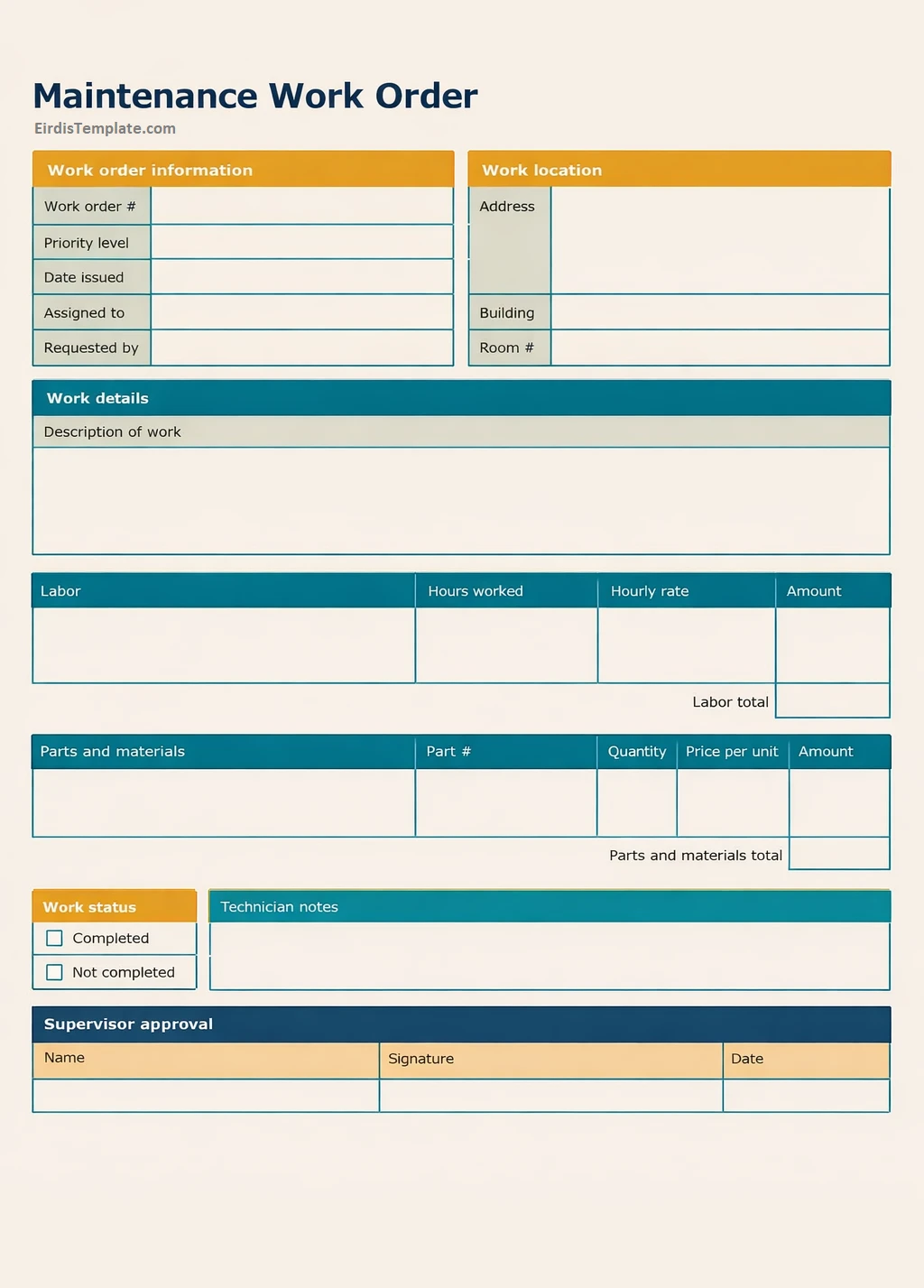

Key Components of Maintenance Work Orders

Maintenance work orders consist of several key components that provide essential information for planning, executing, and tracking maintenance tasks. Understanding the key components of work orders is crucial for creating comprehensive and effective documents that guide maintenance activities and ensure successful outcomes.

Work Order Number and Title

Each maintenance work order is assigned a unique identifier, such as a work order number or title, for tracking and reference purposes. The work order number helps in identifying and distinguishing between different work orders, while the title provides a brief description of the maintenance task to be performed.

Description of Work to Be Performed

One of the most critical components of a maintenance work order is the description of the work to be performed. This section details the scope of the maintenance task, including the specific issue to be addressed, the steps required to resolve it, and any additional instructions or considerations for completing the work.

Location of Work

Information about the location where the maintenance task is to be carried out is essential for ensuring that technicians can easily locate and access the facilities or equipment requiring maintenance. Providing details about the physical location, such as building, room number, or equipment identification, helps in directing maintenance personnel to the correct site of work.

Materials and Parts Required

A list of materials, tools, and parts needed to complete the maintenance task is included in the work order to ensure that technicians have all the necessary resources at their disposal. Listing the required materials helps in proper planning and preparation for the task, reducing delays and interruptions during maintenance work.

Estimated Time for Completion

The estimated time for completing the maintenance task is specified in the work order to provide a timeline for when the work is expected to be finished. This time frame helps in scheduling resources, managing expectations, and prioritizing tasks based on urgency and impact on operations.

Signature and Approval Fields

Work orders typically include signature and approval fields for authorized personnel to sign off on the work order, indicating their acknowledgment and approval of the maintenance task. Obtaining signatures from relevant stakeholders ensures that all parties are aware of the work to be performed, have agreed to the terms outlined in the work order, and are accountable for its successful completion.

Best Practices for Managing Maintenance Work Orders

Effective management of maintenance work orders is essential for optimizing maintenance operations, improving efficiency, and ensuring the longevity of facilities and equipment. Implementing best practices for managing work orders helps organizations streamline maintenance processes, enhance communication and collaboration, and achieve better outcomes in maintenance activities.

Standardize Work Order Processes

Establishing standardized procedures for initiating, reviewing, assigning, and completing work orders is crucial for ensuring consistency and efficiency in maintenance operations. By defining clear workflows, roles, and responsibilities, organizations can streamline the work order process, reduce errors, and improve overall performance in managing maintenance tasks.

Prioritize Work Orders Based on Urgency and Impact

Classifying work orders according to their urgency and impact on operations helps organizations prioritize resources and attention based on criticality. By categorizing work orders as urgent, important, or routine, maintenance managers can allocate resources effectively, address high-priority tasks promptly, and minimize disruptions to operations.

Implement a Digital Work Order Management System

Utilizing a digital work order management system, such as computerized maintenance management software (CMMS), can streamline the work order process, improve efficiency, and enhance visibility and control over maintenance activities. These systems help in creating, assigning, tracking, and managing work orders digitally, providing real-time updates, notifications, and analytics to optimize maintenance operations.

Provide Training for Personnel

Ensuring that maintenance technicians and personnel are adequately trained to understand and execute work orders effectively is essential for maintaining quality and consistency in maintenance tasks. By investing in training programs, workshops, and resources, organizations can empower their workforce to perform maintenance tasks with skill, accuracy, and adherence to best practices.

Regularly Review and Analyze Work Order Data

Monitoring key performance indicators and metrics related to work orders, such as completion rates, response times, and costs, allows organizations to assess the effectiveness of their maintenance practices, identify areas for improvement, and optimize maintenance processes. Regular review and analysis of work order data enable organizations to make data-driven decisions to enhance maintenance operations.

Communicate and Collaborate Effectively

Fostering open communication and collaboration among maintenance teams, facility managers, and other stakeholders is essential for ensuring the successful completion of work orders. By promoting a culture of teamwork, sharing information, and coordinating efforts, organizations can improve coordination, resolve issues efficiently, and achieve better outcomes in managing maintenance tasks.

Implement Preventive Maintenance Strategies

Incorporating preventive maintenance strategies into maintenance work orders can help organizations proactively address potential issues before they escalate into critical problems. By scheduling routine inspections, preventive maintenance tasks, and condition-based monitoring, organizations can reduce the likelihood of unexpected breakdowns, extend the lifespan of equipment, and improve overall reliability.

Track and Analyze Maintenance Trends

Monitoring and analyzing maintenance trends, patterns, and historical data from work orders can provide valuable insights into recurring issues, maintenance needs, and opportunities for optimization. By identifying common problems, root causes, and areas for improvement, organizations can implement proactive measures, streamline processes, and enhance maintenance efficiency.

Establish Key Performance Indicators (KPIs)

Defining and tracking key performance indicators (KPIs) related to maintenance work orders, such as completion times, costs, and customer satisfaction, can help organizations measure performance, identify trends, and benchmark progress over time. Establishing KPIs allows organizations to set goals, monitor performance, and drive continuous improvement in maintenance operations.

Implement a Feedback Mechanism

Creating a feedback mechanism for maintenance work orders enables stakeholders to provide input, suggestions, and comments on the effectiveness of maintenance tasks and processes. By soliciting feedback from maintenance technicians, customers, and other stakeholders, organizations can gather insights, address issues, and make adjustments to improve overall maintenance performance.

Invest in Technology and Innovation

Embracing technology and innovation in maintenance management, such as predictive maintenance tools, Internet of Things (IoT) sensors, and artificial intelligence (AI) algorithms, can revolutionize maintenance practices and enhance the effectiveness of work orders. By leveraging cutting-edge technologies, organizations can improve asset reliability, reduce downtime, and optimize maintenance operations.

Continuously Improve and Adapt

Maintaining a mindset of continuous improvement and adaptability is essential for staying agile and responsive to changing maintenance needs and challenges. By fostering a culture of learning, innovation, and flexibility, organizations can adapt to new technologies, trends, and best practices, ensuring that maintenance work orders remain effective and efficient in supporting facility operations.

Conclusion

In conclusion, maintenance work orders are indispensable tools in facilities management for ensuring the efficient and safe operation of facilities and equipment. By authorizing and detailing maintenance tasks, work orders facilitate task management, resource allocation, and historical tracking of maintenance activities.

Understanding the types, process flow, key components, and best practices for managing maintenance work orders is essential for optimizing maintenance operations, improving efficiency, and achieving better outcomes in maintaining facilities. By incorporating best practices, leveraging technology, and fostering a culture of collaboration and continuous improvement, organizations can enhance their maintenance processes, reduce downtime, and prolong the lifespan of their assets.

Maintenance Work Order Template – DOWNLOAD

- Free Nurse Resignation Letter Template (Word) - February 28, 2026

- Free Printable Nursing Notes Template - February 27, 2026

- Free Editable Nursing Resume Template (Word) - February 23, 2026